Anyone who’s been under the dash to replace anything can appreciate paying someone else to handle it. Dash work is best performed by those 12 year old world class gymnast types who can bend in half. When I walked into the shop yesterday and saw Chip contorted underneath the dash of this big Healey, I knew he was earning his keep. The heater control valve on this car was quite corroded and plugged, so he was installing a new one to eliminate the leak emptying into the footwell of this car. Another look at the overall scene:

Anyone who’s been under the dash to replace anything can appreciate paying someone else to handle it. Dash work is best performed by those 12 year old world class gymnast types who can bend in half. When I walked into the shop yesterday and saw Chip contorted underneath the dash of this big Healey, I knew he was earning his keep. The heater control valve on this car was quite corroded and plugged, so he was installing a new one to eliminate the leak emptying into the footwell of this car. Another look at the overall scene:

Odd Jobs – Waxstat Carburetors

Waxstat carburetors seemed like a good idea. Use one mixture when the engine is cold, then have a temperature sensitive adjuster change the mixture once the motor warmed up. Sounds rather modern, frankly. In real life, these SU’s with waxstats didn’t execute so well. So, Chip is converting them and removing the waxstats. To get philosophical, your humble webmaster, who is no mechanical genius, has never opposed a simple manual choke and wonders exactly why they fell out of favor.

Waxstat carburetors seemed like a good idea. Use one mixture when the engine is cold, then have a temperature sensitive adjuster change the mixture once the motor warmed up. Sounds rather modern, frankly. In real life, these SU’s with waxstats didn’t execute so well. So, Chip is converting them and removing the waxstats. To get philosophical, your humble webmaster, who is no mechanical genius, has never opposed a simple manual choke and wonders exactly why they fell out of favor.

On the other side of the shop, Dean has been assembling this TR4 engine for a customer’s car. I’ll try to get another picture when it’s all completed. Stay tuned.

On the other side of the shop, Dean has been assembling this TR4 engine for a customer’s car. I’ll try to get another picture when it’s all completed. Stay tuned.

TR6 Front Suspension Work

Chip noticed some squeaking in the front end of the project TR6 and decided to replace some bushings in the front end with Richard Good Nylatron bushings.

Above are the offending squeakers.

Above are the offending squeakers.

This photo shows the new bushings install on the lower control arm. Chip also inverted the control arm to lower the car a bit. This car will also get Spax shocks on the front and new springs. After all of that, we can get it off the rack and note any improvement.

This photo shows the new bushings install on the lower control arm. Chip also inverted the control arm to lower the car a bit. This car will also get Spax shocks on the front and new springs. After all of that, we can get it off the rack and note any improvement.

MGB Floorboards

A customer asked us to check on the floorboards in his MGB, so we peeled out the carpet and found this on the passenger’s side. All of the dark spots are holes. It appears that someone had tried to use some type of substance to fill holes previously, putty maybe? A common cause of this problem is leaving the carpets in the car after they get wet rather than pulling them out to dry. That traps moisture in the car for a long period of time. This car needs floorboards on both sides.

A customer asked us to check on the floorboards in his MGB, so we peeled out the carpet and found this on the passenger’s side. All of the dark spots are holes. It appears that someone had tried to use some type of substance to fill holes previously, putty maybe? A common cause of this problem is leaving the carpets in the car after they get wet rather than pulling them out to dry. That traps moisture in the car for a long period of time. This car needs floorboards on both sides.

Above is the driver’s side with a light underneath for effect. It’s a little better than the passenger’s side but not by much. Chip will confer with the owner to see how he wants to proceed at this point.

Above is the driver’s side with a light underneath for effect. It’s a little better than the passenger’s side but not by much. Chip will confer with the owner to see how he wants to proceed at this point.

Meet The 510

Happy New Year, and look at that Datsun 510 on the lift. It has so much, ah, potential. Never fear, we’re talking Chip Collingwood and his years of experience, so if you’re worried about the fate of this tired 510, relax and listen to the plans we have. Chip’s going to build an L20B motor that he already has to go into the car to replace the original 1600 motor. The L20B will get a laundry list of hop up parts to include improved carberation, headers, perhaps some headwork… the usual stuff.

Happy New Year, and look at that Datsun 510 on the lift. It has so much, ah, potential. Never fear, we’re talking Chip Collingwood and his years of experience, so if you’re worried about the fate of this tired 510, relax and listen to the plans we have. Chip’s going to build an L20B motor that he already has to go into the car to replace the original 1600 motor. The L20B will get a laundry list of hop up parts to include improved carberation, headers, perhaps some headwork… the usual stuff.

Above is a photograph of the rear crossmember that Chip modified (just a little cutting and welding) to be adjustable for camber and toe. Helpful adjustments if you lower the car for handling, which could happen here.

Above is a photograph of the rear crossmember that Chip modified (just a little cutting and welding) to be adjustable for camber and toe. Helpful adjustments if you lower the car for handling, which could happen here.

The current task is stripping the interior down to metal. Then it gets POR15’d as extra insurance, primed, and Lizard-skinned. After the interior is in good shape, Chip will start on stripping and blasting the exterior. Before anyone asks, yes, we have the doors for the car. Also before anyone asks, yes, we are going to put them back on before we drive it. Stay tuned for updates on the 510 build.

The current task is stripping the interior down to metal. Then it gets POR15’d as extra insurance, primed, and Lizard-skinned. After the interior is in good shape, Chip will start on stripping and blasting the exterior. Before anyone asks, yes, we have the doors for the car. Also before anyone asks, yes, we are going to put them back on before we drive it. Stay tuned for updates on the 510 build.

Datsun 2000 Update

Work is drawing to a close on the ’68 2000 Roadster we have in the shop. The owner took a spin recently and certainly approves of the more compliant ride. That’s what happens when you back the Koni’s off from full stiff. The last little item is some slight tuning of the idle circuit jets in the Solex carbs. It’s not quite as crisp as it could be on transitions. Chip will sort that out and this car will be ready to roll. We want to thank the owner for sharing his car with us. It was a treat to work on.

Work is drawing to a close on the ’68 2000 Roadster we have in the shop. The owner took a spin recently and certainly approves of the more compliant ride. That’s what happens when you back the Koni’s off from full stiff. The last little item is some slight tuning of the idle circuit jets in the Solex carbs. It’s not quite as crisp as it could be on transitions. Chip will sort that out and this car will be ready to roll. We want to thank the owner for sharing his car with us. It was a treat to work on.

Austin Healey 3000

We’re set to do some freshening on an Austin Healey that was restored somewhere in the neighborhood of 15 years ago. Maintenance items include securing a banging exhaust, flushing the brake lines and replacing the fluid, replacing the oil with Brad Penn oil that contains ZDDP, pondering the pros and cons of electronic ignition, adjusting the valves, and checking the suspension and greasing the tie rods.

We’re set to do some freshening on an Austin Healey that was restored somewhere in the neighborhood of 15 years ago. Maintenance items include securing a banging exhaust, flushing the brake lines and replacing the fluid, replacing the oil with Brad Penn oil that contains ZDDP, pondering the pros and cons of electronic ignition, adjusting the valves, and checking the suspension and greasing the tie rods.

I’d like to elaborate on the Brad Penn oil (full disclosure: we sell it). Years ago, most oils had zinc in them. Some current oils don’t, which doesn’t have much effect on newer engines. But, in old engines with flat tappets, the zinc protects the tappets from wear.

We see it as cheap insurance and that’s why we use it. Stay tuned as we log improvements on the Healey.

We see it as cheap insurance and that’s why we use it. Stay tuned as we log improvements on the Healey.

1976 Triumph TR6 Tuning

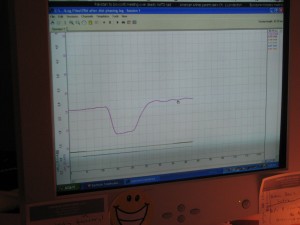

Thought I’d introduce another tool Chip is using to tune the TR6. It’s a software program that plots the Air/Fuel mixture ratio using a sensor mounted in the exhaust. This little tool helps to see how close we are getting to complete combustion. If anyone is wondering, we are currently a bit rich, so we can lean it out a bit. Our formerly weak ignition (see the previous article discussing Distributor Phasing) needed more fuel, whereas the properly functioning ignition requires less. We like efficiency.

Thought I’d introduce another tool Chip is using to tune the TR6. It’s a software program that plots the Air/Fuel mixture ratio using a sensor mounted in the exhaust. This little tool helps to see how close we are getting to complete combustion. If anyone is wondering, we are currently a bit rich, so we can lean it out a bit. Our formerly weak ignition (see the previous article discussing Distributor Phasing) needed more fuel, whereas the properly functioning ignition requires less. We like efficiency.

1976 TR6 Ignition Phasing

Ignition what? Read on, I’ll explain.

Ignition what? Read on, I’ll explain.

Adjustments continue towards the goal of maximizing the efficiency and response of the stock tuning on the ’76 TR6. Chip wants to get the car running as well as possible to serve as an accurate baseline prior to making any improvements. The latest adjustments were motivated by a miss that developed after a long highway run.

Chip went to a meeting in the Fredericksburg, VA area that facilitated running the non-overdrive, 4-speed TR6 an extended period of time on Interstate 95 at moderately high revs. The car ran well on the trip up. On the return trip home, an intermittent miss developed, leading Chip on a search for the cause.

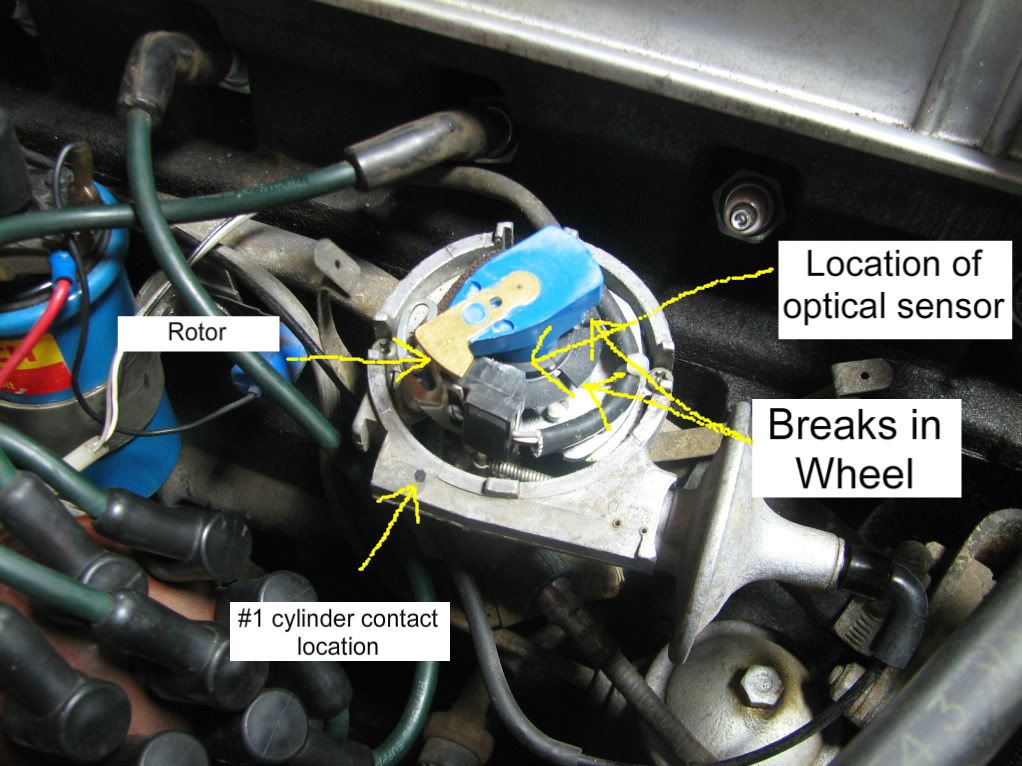

It turns out that while the timing on the car was set correctly (the plug fired when the piston was at 10 degrees Before Top Dead Center with the vacuum retard disconnected), the spark was weak because the rotor was not lined up where it should be at firing time (it was out of phase). Take a look at the picture below for an explanation and please forgive the crude labels.

In the picture above, the distributor cap is off. The black dot is the location of the #1 cylinder contact location when the cap is on, so that’s where the rotor should be at firing time, just like it is in the picture. The distributor in the picture is phased correctly (now). Prior to the fix, the rotor was about 20 degrees past it’s intended firing position, which made an awfully long arc for the signal to jump.

In the picture above, the distributor cap is off. The black dot is the location of the #1 cylinder contact location when the cap is on, so that’s where the rotor should be at firing time, just like it is in the picture. The distributor in the picture is phased correctly (now). Prior to the fix, the rotor was about 20 degrees past it’s intended firing position, which made an awfully long arc for the signal to jump.

In order for the distributor to fire correctly, the rotor should line up with the cylinder contact at the same time the optical sensor (see picture) lines up with the break in the wheel. There are six breaks (one for each cylinder). The optical sensor is facing away from us and towards the center of the distributor.

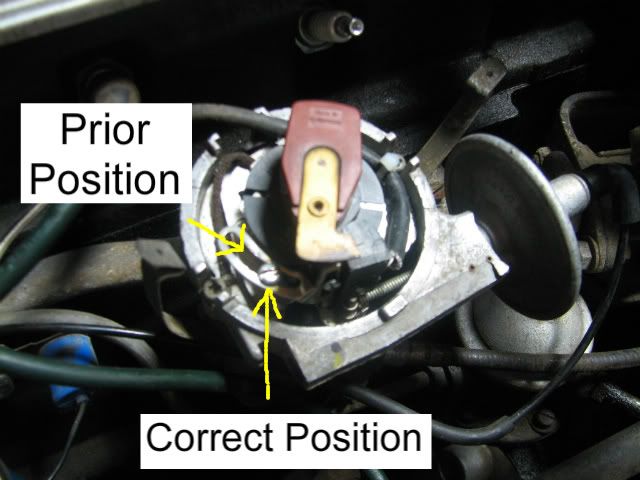

Above is a picture of the distributor from the other side (optical sensor is now at the 12 o’clock position) without the rotor. It’s a tad out of focus, but it helps to see how the breaks line up with the optical sensor. Now, let’s go back to the other side and look at one last thing.

Above is a picture of the distributor from the other side (optical sensor is now at the 12 o’clock position) without the rotor. It’s a tad out of focus, but it helps to see how the breaks line up with the optical sensor. Now, let’s go back to the other side and look at one last thing.

The picture above shows the distributor with the cap removed. We had a different rotor on at this time, so that’s why it’s not the blue one. The yellow arrows in this photo point to the adjustment available. Previously, the rotor was rotated a good 20 degrees counterclockwise (yellow arrow “Prior Position”) from where it is now, which resulted in it being a good ways past the dot marking the number one cylinder contact. Since everything didn’t line up like it is supposed to, the spark was weak.

The picture above shows the distributor with the cap removed. We had a different rotor on at this time, so that’s why it’s not the blue one. The yellow arrows in this photo point to the adjustment available. Previously, the rotor was rotated a good 20 degrees counterclockwise (yellow arrow “Prior Position”) from where it is now, which resulted in it being a good ways past the dot marking the number one cylinder contact. Since everything didn’t line up like it is supposed to, the spark was weak.

Weak spark or not, the car ran fine for a while, a testament to the strength of the ignition. Eventually, however, running at over 3000 r.p.m.s for an extended time caused one of the spark plugs to go bad, which caused the miss Chip was hearing.

Credit for help in the diagnosis goes to Jeff Schlemmer of Advanced Distributors. Chip has sent numerous distributors to Jeff and has been very pleased. Jeff commented that he has seen phasing effects increase in prominence with the advent of electronic ignition retrofits to older cars. Jeff is a wealth of knowledge and well worth a call if you need a distributor resource.

So here’s the bottom line: when all of the ignition components weren’t lining up correctly, it caused problems with the ignition (bad plug) that led to a miss. Once Chip corrected that, the car runs like a top… which is what we’re after. Now that the car is running well, we can experiment with the effects of advancing the timing to 12 or 14 degrees BTDC. We’ll keep you updated.

1976 TR6 Out of Storage

Chip ran across a 1976 TR6 that had been sitting for a number of years. I think 7 is the number, if I remember correctly. The clear coat is peeling off, making the car look neglected. Chip saw some things he liked about it, however, such as the Panasport wheels and the fact that, other than sitting, it looked to be pretty functional. This would be a great moment to include a shot of the overall car if I had one, which, inexplicably, I don’t. I’ll put it on the list. (Click on any of the photos below to enlarge them).

Here’s a shot of the front of our beauty queen. Somewhere along the way, someone installed an aluminum gas tank, which helps much from a corrosion standpoint. Chip removed the tank from the car, cleaned it, installed a new fuel line, cleaned the carbs, and it started after all those years of sitting.

Here’s a shot of the front of our beauty queen. Somewhere along the way, someone installed an aluminum gas tank, which helps much from a corrosion standpoint. Chip removed the tank from the car, cleaned it, installed a new fuel line, cleaned the carbs, and it started after all those years of sitting.

Above is the view during the gas tank cleaning. The tank was out of the car at this point and is pictured below.

Above is the view during the gas tank cleaning. The tank was out of the car at this point and is pictured below.

Future plans for this car call for some cylinder head work, a slightly more aggressive cam, and fuel injection. Stay tuned for further updates.

Future plans for this car call for some cylinder head work, a slightly more aggressive cam, and fuel injection. Stay tuned for further updates.