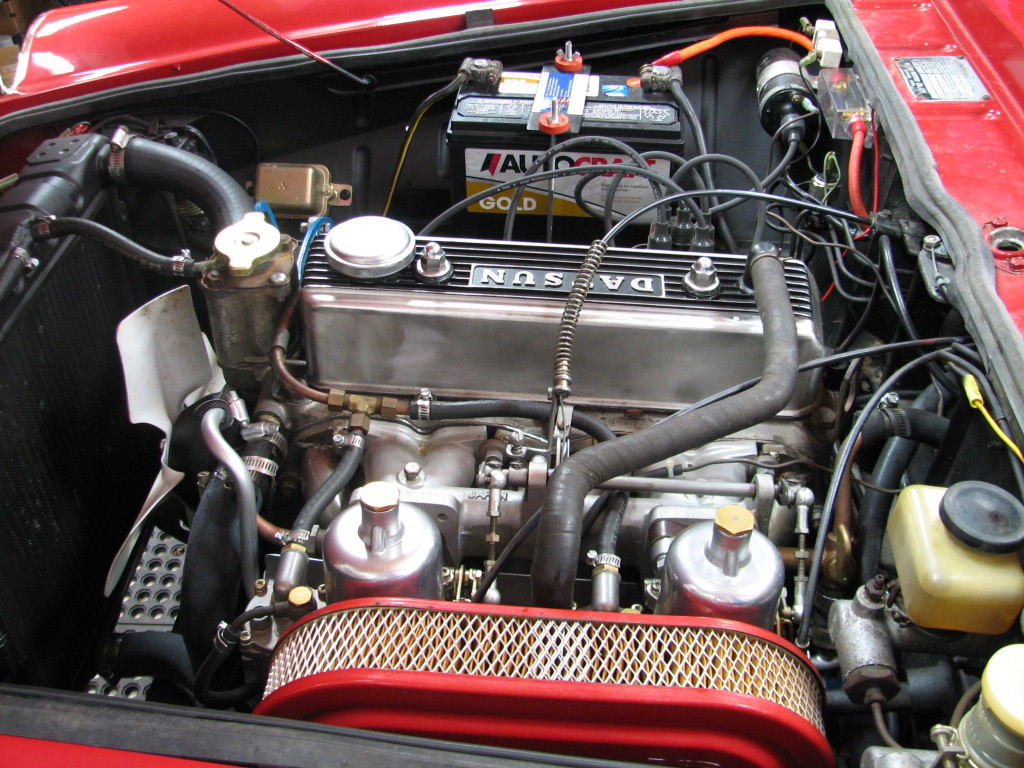

This Datsun 1600 came in for some brake work and other odds and ends. I like these cars and they seem to be growing in popularity. Either that, or they’re already popular and I hadn’t noticed. All of the 1600s I’ve seen at the shop have been red. Did they make any other colors? There are worse things than working on clean, red Datsuns all day long.

TR4A with Replacement Frame Back on the Ground

Ah… relief. The TR4A that used to have a rotted rear frame is down off the stands and on its own wheels with a replacement frame section. In addition to frame section Chip put in, Dean has fixed or replaced numerous other components on the car. Start-up and tuning are next on the list.

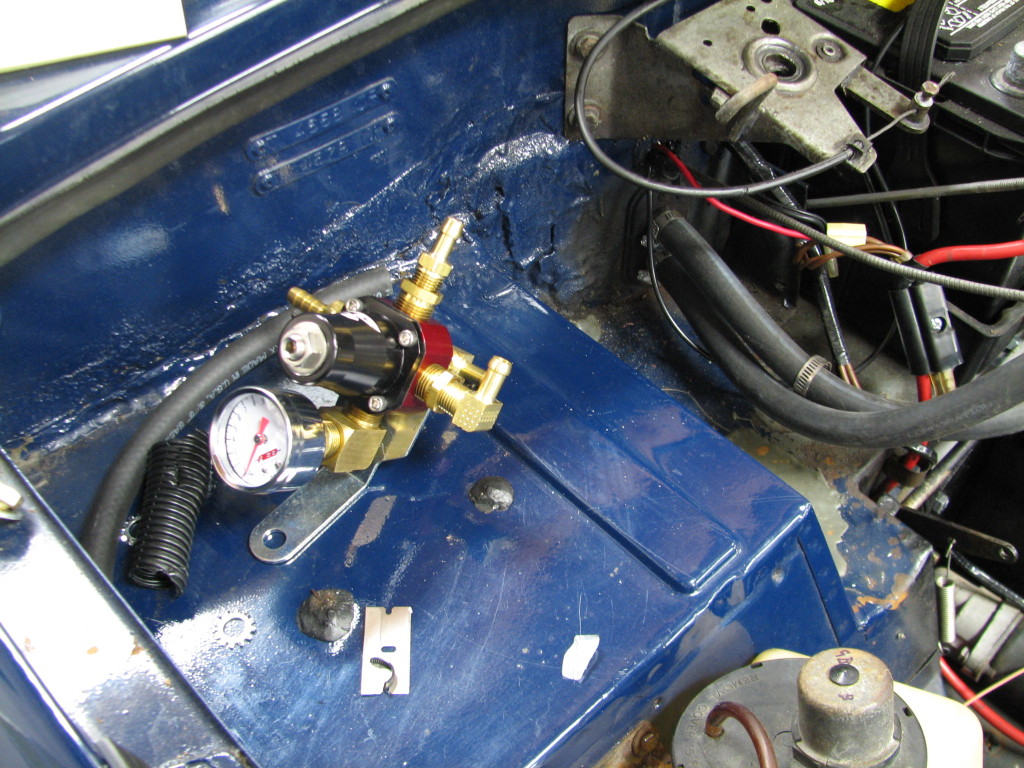

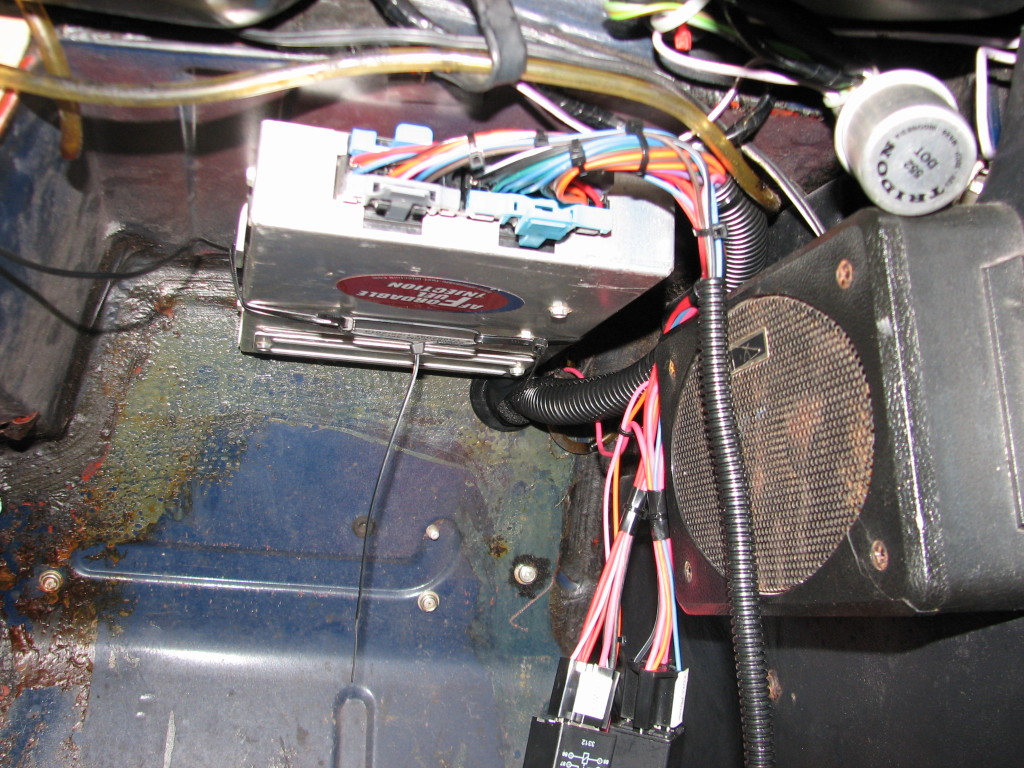

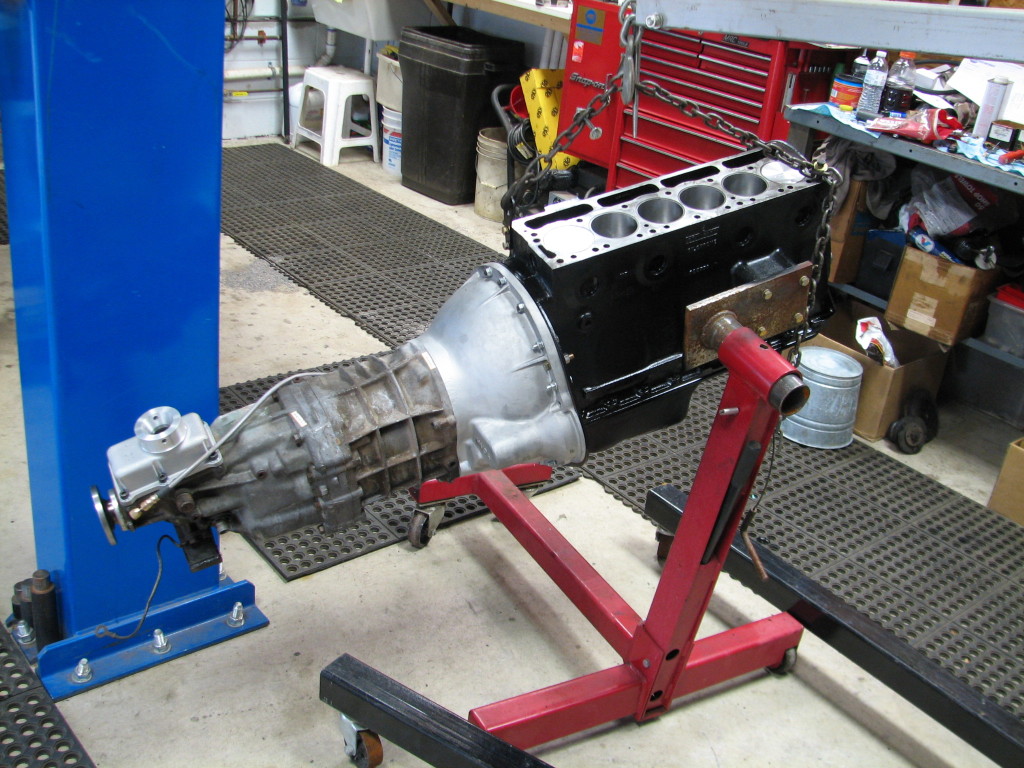

TR6 Receiving Toyota 5-Speed and Fuel Injection

This car is in for the works and I’ve mentioned it before. Now, it’s moving along. The motor’s been refreshed, there is now a Toyota 5-Speed installed, and fuel-injection is in process. It will be a great driving car when it’s all buttoned back up. If you have any interest in either the fuel-injection upgrade, the 5-speed conversion, upgrading to Toyota brake calipers or any other improvements with your old British Classic, call if you would like to consult with us beforehand.

Triumph TR6 Toyota Five Speed Conversion

Triumph Dove Engine Removal and Archaeology

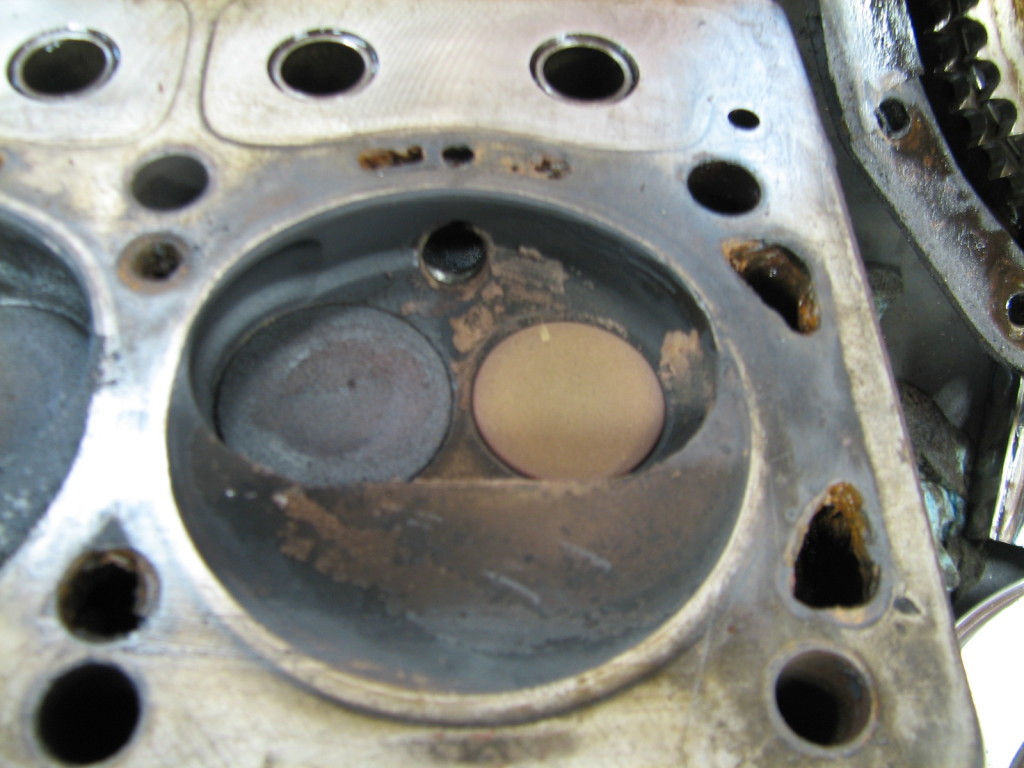

The Triumph Dove that came in with a No-Start condition has been a fascinating experience (for me, the web guy). During the engine removal and disassembly process, I got to see the evidence of an engine that has run too hot and paid the price. The “story” of all the existing damage we saw makes sense (it all “adds up”, if you will), which makes us confident we can put it right. The oil in the oil filter didn’t even flow at room temperature. It shook like a literal bowl full of jelly. It was cooked. Let’s take a look at some of the things we saw.

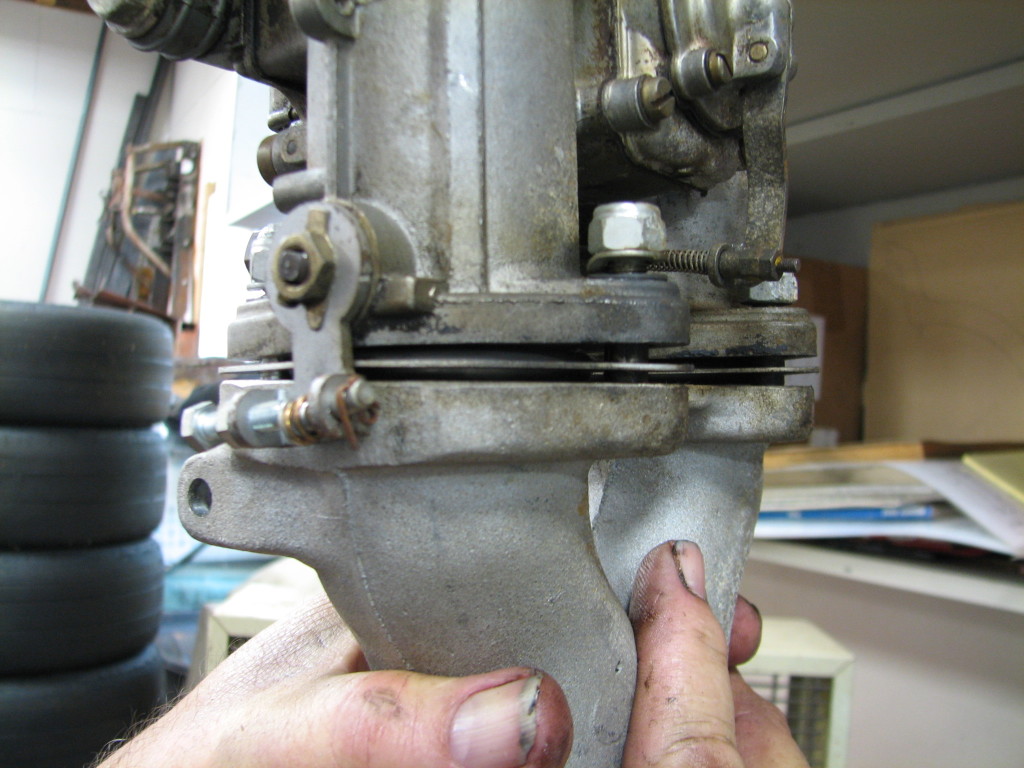

This photo shows Dean holding one of the carbs in the air as it is mounted on the intake. He took the intake off the motor and left the carb just like it was. His hand is holding the intake. You can see looking at the junction where the carb and it’s rubber gasket meet the intake that there is a gap. There is not supposed to be a gap. The gap is allowing extra air in, which results in a lean condition. Dean saw other indications that this motor was running very hot, and the lean condition suffered by the cylinders fed by this carburetor would only make that (running hot) worse.

Looking at the cam lobe in the center of the picture, you can see that the lobe is worn down. The discoloration in the metal makes it easy to see in the picture.

My, oh my, this rod bearing has had it. The crankshaft and rod bearing scored each other until the motor locked up. Once Dean took the cap off of this rod, the motor turned.

I couldn’t get a shot with the camera to show the wear on these tappets. However, if you saw it live, you would immediately recognize the dished appearance of the tappet to be a problem. If you don’t look at flat tappets frequently, you would at least ask, “Say, is that dished out shape on the top of that tappet normal?” No, it’s not normal at all. For that exact reason (tappet wear on old style flat tappets), we use oil with Zinc (ZDDP additive) when we do oil changes on these old cars. Most newer cars have roller tappets and the zinc is not an issue. New oil standards do not have as much zinc in them because newer engines don’t need as much.

Note the position (in the cylinder head) of the valves on this cylinder relative to the next picture.

Those are the highlights from this particular engine. Fairly informative, I must say. Next, we’ll order needed parts and have the machine work done.

That Red TR4A – Replacement Frame Section Going In

Man, what a project. Nothing for the pros, mind you, but I’m not one of those. If you’d like to start at the beginning, here’s a chronological list of the updates:

This week, Chip has started welding in the replacement rear frame section. After this is all in and the body bolted down, it’s time to install a gas tank and see if it will start. I will keep you posted. Pictures: (Pardon the strange angles here. I’m on a creeper for these.)

Corvette with New Paint

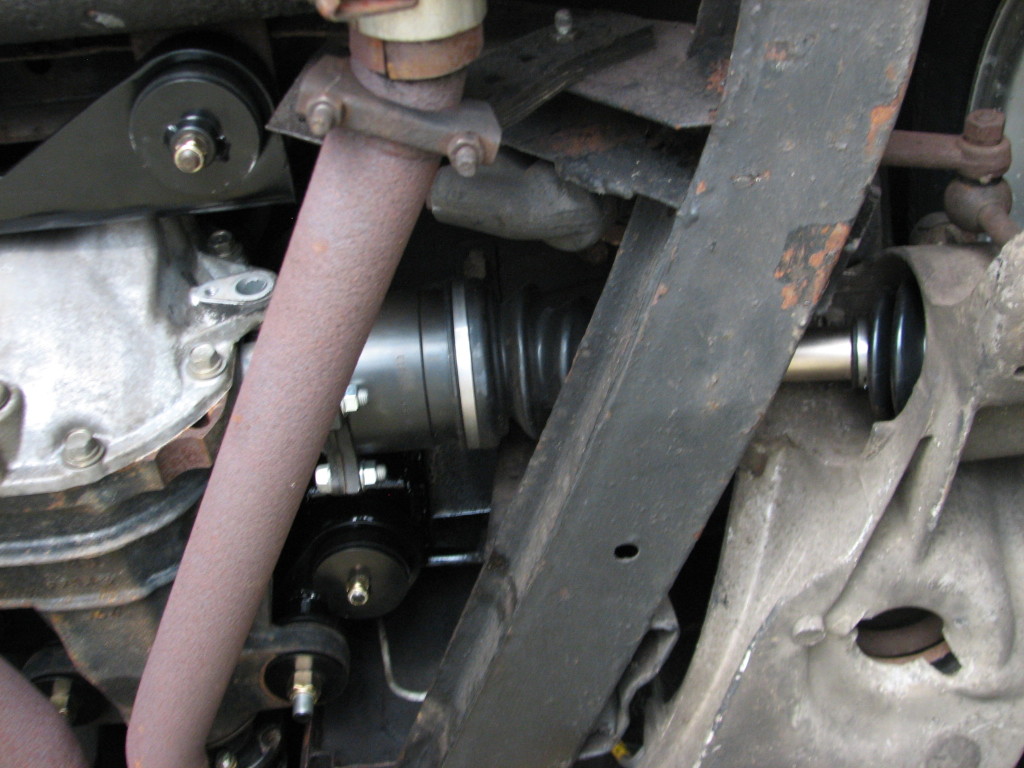

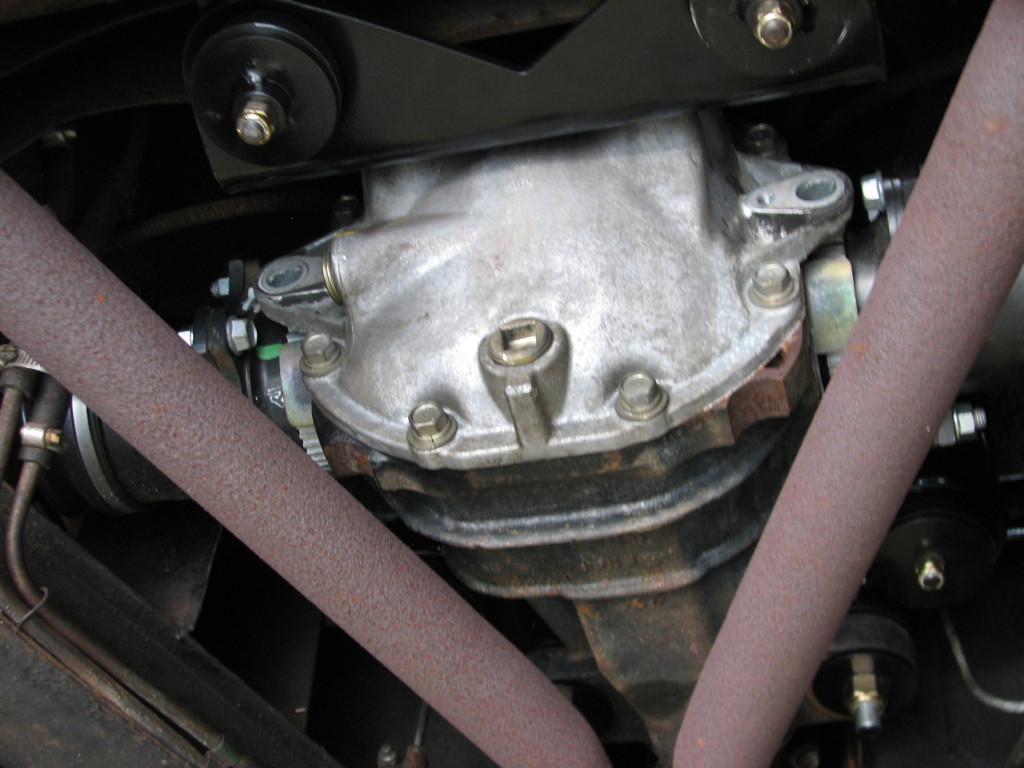

Triumph TR6 with Richard Good Axle Conversion and Nissan Differential

I snapped a few pictures from underneath the TR6 with the Nissan differential installed and the Richard Good CV Joint axles. It’s a very nice setup. If you have questions about whether it’s a good idea for your car, give Chip or Dean a call. See our “Contact Us” page for contact information.

Triumph TR6 Differential and Richard Good Axle Conversion

Triumph TR6 Steering Column Re-do

Just a couple of pictures from some minor steering column maintenance that Chip was working on. In the “You Learn Something New Every Day” category, I learned that there are pieces of felt that belong here among the collection of parts that comprise the steering column. Who knew? Chip was replacing those pieces and likely some other parts as well to make everything feel as good or better that it is supposed to feel.